Sheet metal bending is a manufacturing process of shaping flat metal sheets into various shapes and structures for practical use. In this technique, we apply force on special points and lines to create bends, curves, and angles. This process is essential in making different products. These products include household items as well as industrial parts. This article will explore the importance of sheet metal bending in the domain of the consumer goods industry.

Table of Contents

Consumer Goods that Use of Sheet Metal Bending

The sheet metal bender process is widely used in making industrial products. It plays a vital role in the manufacturing of different items of daily use. The consumer goods industry includes shaping products for our ease. Here we will go through the use of sheet metal bending in the consumer goods industry. We will explain how sheet metal manufacturing relates to each category.

Electronic Devices

Sheet metal is often used to manufacture enclosures and casings for electronic equipment. The sheet metal has thin, light, and strong properties. Previously mentioned abilities make it an ideal material for protecting electronic components.

Personal Wellness Products

Sheet metal fabrication can be used to create parts for wellness products. These wellness products include exercise equipment, massage chairs, and even medical device components. The precision of sheet metal makes it easy the create complex designs and structures.

Athletics and Sporting Equipment

Sports equipment such as fitness equipment, weight benches, and various equipment components can be manufactured from sheet metal. It has high strength and elasticity. This makes it suitable for manufacturing well-made and functional sports equipment.

Cookware Products:

Sheet metal, primarily stainless steel, is often used to manufacture various cookware. Such as pots, pans, baking sheets, and multiple others. It can conduct heat uniformly and withstand high temperatures. This facility makes it popular in the production of kitchenware.

Wearable Devices:

The nature of sheet metal is lightweight and slim. This makes it suitable for components in wearable devices. The wearable devices are such as smartwatches and fitness trackers. This enables the production of thin but long-lasting cases.

Ancillary Components:

The ancillary and peripheral components consist of small brackets to decorative elements. It provides a cost-effective and efficient way to manufacture different accessories. Ancillary products act like a bounty object with a main deal. Their usage is different in medical, baking, automobiles, tractors, and many other industries.

Virtual Reality Products:

Sheet metal can be used to create sections and structural parts for virtual reality devices. Its creativity allows for the manufacture of difficult designs. These complex designs are produced while providing the necessary structural support.

Furniture

Sheet metal is sparingly used to build beautiful furniture. Furniture, shelving units, and decorative items within furniture are often made of sheet metal. It can be molded into different shapes to create modern and stylish designs.

Smart Home Products

Many smart home products are created using metal sheet bending. These products include thermostats, security cameras, smart light fixtures, and many more. This ensures the durability and protection of the internal electronic elements. It has great strength and the ability to shield electronic components. This makes it a suitable material for many smart home applications.

Sheet Metal Bending Methods in the Consumer Goods Industry

The metal sheets are transformed in several ways to get the desired shapes. All methods of bending performed the same task of molding sheets. However, the operations performed by all metal sheets are quite different. These molding methods depend on various factors like the thickness of the bend, size of the bend, and radius of the sheet metal bend. Given below are a few methods of how sheets are bent.

-

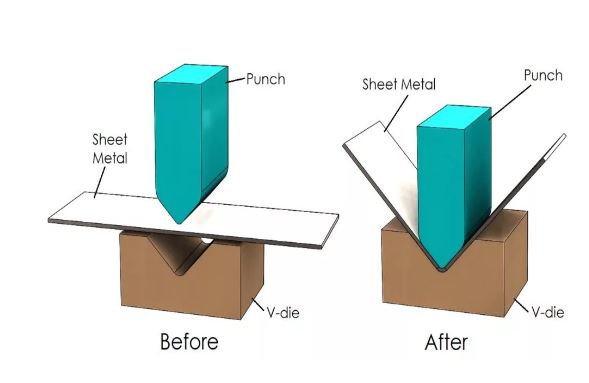

V Bending:

V-bending is a handy way to shape sheet metal, often done with a press brake machine. Picture a V-shaped tool (die) and a matching part (punch) working together. The sheet metal goes between them, and when the machine applies pressure, the metal bends to fit the V-shape. How much it bends is controlled by how far down the punch goes. V-bending is super flexible, working well with different materials and thicknesses. It’s good for making simple shapes, like brackets or panels, quickly and precisely. V bending has different subtypes:

Alt text: V Bending

-

Bottoming:

Bottoming, also known as bottom bending, involves the punch fully contacting the bottom of the V-shaped die. This method results in a precise and well-defined bend angle, making it suitable for applications that require high accuracy.

-

Coining:

Coining is an extreme form of bottoming where significant pressure is applied to deform the sheet metal into the shape of the die. This method produces highly precise and detailed bends, making it suitable for intricate parts.

-

Air bending

In air bending, the punch descends and presses the sheet metal into the V-shaped die, but it doesn’t make full contact with the bottom of the die. The bend angle is determined by the material’s elasticity. Air bending is flexible and suitable for various materials and thicknesses.

-

Gooseneck Punch

A gooseneck punch has a curved or extended shape that allows for bending in locations that may be challenging with a standard punch. It is particularly useful for reaching into deep recesses or tight spaces.

-

Radius Bending

Radius bending involves using a punch and die with a specific radius to create bends with rounded corners. This method is often employed when a softer appearance is desired, and it can be crucial for certain aesthetic or functional requirements.

Each type of V-bending has its advantages and is chosen based on factors such as the desired bend angle, material characteristics, and specific requirements of the application.

-

Roll bending:

Roll bending is a metal shaping technique that involves passing a flat sheet of metal through a series of rollers to gradually curve or shape it. In this process, the metal sheet is fed between three rollers—one in the center and two on the sides. As the sheet moves through, the rollers apply pressure, bending the metal to the desired curvature. This method is particularly useful for creating cylindrical shapes, tubes, or rounded sections in various materials.

Alt text: Roll Bending

-

U bending:

U-bending is a sheet metal bending technique that creates a U-shaped bend in a metal workpiece. This method is commonly used in various industries to form components with a distinctive U-shaped profile, offering versatility in manufacturing diverse products.

Alt text: U Bending

-

Wipe bending:

Wipe bending is a sheet metal forming process where the metal is bent around a contour or form, resulting in a curved or irregular shape. This technique is particularly useful for creating components with complex geometries, allowing for precise shaping of the metal along a defined contour.

Alt text: Wipe bending

-

Rotary bending:

Rotary bending is a sheet metal forming method that utilizes rollers to bend metal along a curved axis. This technique is effective for creating cylindrical or conical shapes in a range of materials, providing a versatile solution for manufacturing applications that require smooth and continuous curves.

Alt text: Rotary Bending

Companies that use Sheet Metal Bending

Many companies use sheet metal bending to shape components for various purposes. Whether creating bends in HVAC ducts or forming curves in automotive panels, this process is essential. Sheet metal bending is cost-effective and efficient, allowing businesses to easily meet design requirements and produce components that fit seamlessly into their final products. We have researched some companies that excel at using bending technology in consumer products.

-

BMW

BMW is known for the design of elegant, aerodynamic luxury cars. The automotive uses advanced sheet metal bending to create its vehicle bodies. It also contributes to the unique shapes and outlines representing the BMW brand.

-

Dyson

Dyson is a leading provider of creative home appliances. It is especially known for its vacuum cleaners and bladeless fans. Dyson products often feature precisely curved metal components. This characteristic demonstrates attention to form and function. The smart, modern design of Dyson machines requires complex bending techniques.

Alt text: Dyson vacuum cleaner

-

Samsung:

Samsung is a global technology giant that manufactures a wide range of consumer electronics products. Samsung uses sheet metal bending to manufacture high-end smartphones, tablets, and consumer electronics. This not only increases the durability of the product but also contributes to a modern and stylish look.

-

Herman Miller:

Herman Miller is a famous furniture manufacturer known for its beautiful comfortable designs. The company uses sheet metal bending to create frames for chairs and other furniture, creating the perfect blend of comfort and modern design.

-

Whirlpool:

Whirlpool is a leading appliance brand specializing in kitchen and laundry appliances. Whirlpool uses sheet metal bending to manufacture refrigerators, ovens, and washing machines. This ensures the fastness of the device while providing a stylish, space-saving design.

These companies show a concern about using superior bending techniques. This duty is to produce consumer products that not only meet functional requirements but also excel in design and invention.

Top 5 tips for bending steel metal:

Check out these 5 easy tips to make your steel bending adventure easier.

Get the right tools

Choose the right tool for the steel, such as a press brake or a heavy-duty vise. Using the right tools will make bending much easier and cleaner.

Measure carefully

Measure twice before bending once. Please double-check the size to avoid mistakes.

Follow the grain

Steel, like wood, has a grain direction. Bend along the grain direction to prevent cracking and ensure stability.

Make small turns at a time

Make slow turns instead of forcing them into large turns. Gradual bending increases the effect and keeps the steel looking smooth.

Wear your safety equipment

Don’t forget your safety equipment. Wear gloves and safety glasses to protect yourself from sharp edges.

Challenges for the consumer goods industry

The sheet metal bending is the most widely used technique nowadays. Just like everything, this industry also has to face some challenges in its progress. A few of those challenges are given below:

-

Accuracy Difficulties:

Accurate bends are difficult to achieve and can result in defects in the final product.

-

Material considerations:

Different metals may not bend the same, creating consistency issues.

-

Complex Shapes:

Creating complex shapes can make it difficult to maintain precision and uniformity.

Solutions and Innovations:

Every problem in this world has a solution. Regarding this, the solutions for the challenges faced by the consumer goods industry have their solutions. Here is a glance at the solutions:

-

Advanced Machinery:

High-tech machines with precise controls increase precision and ensure every bend is done just right.

-

Materials Expertise:

Innovation in understanding different metals allows bending techniques to be tailored to each type while maintaining quality.

-

Computer-Aided Design (CAD):

The use of CAD technology helps in the design and visualization of complex shapes and ensures accuracy in the bending process.

Conclusion:

The demand for custom products will never end. Because of this, custom metal products require sheet metal bending skills. It’s not just about looking good. It is to make the production process more powerful, more individual, and more cost-effective. Therefore, in this article, we talked about sheet metal, its importance, and what you need to know to bend sheet metal into the desired shape.

FAQs:

What is the best sheet metal bending method?

Determining the best sheet metal bending method can be challenging as each method serves a distinct purpose, resulting in various shapes. The optimal choice depends on the specific requirements of the material being formed.

For example, a common method for bending sheet metal is the “v-bending” technique. In this process, a V-shaped die and punch are used to bend the metal along a straight axis. This method is suitable for creating crisp bends in thin sheets.

If you find the sheet metal bending process challenging or if your project requires precision beyond your expertise, consider seeking assistance from professional metal bending services. Reputable suppliers such as Zintilon provide specialized expertise and equipment, ensuring that your sheet metal bending needs are met efficiently and accurately. Remember, it’s always wise to consult with professionals when faced with intricate bending requirements to achieve the best results.

Is sheet metal easy to bend?

Bending steel plates can present a moderate level of difficulty. However, mastering the process becomes straightforward with a genuine understanding of the techniques involved. It’s essential to familiarize yourself with the tools available for the job.

If you find that bending sheet metal proves challenging for personnel or if your project demands a level of expertise beyond your current capabilities, consider enlisting the assistance of a professional metal bending fabricator. Reputable fabricators like Zintilon possess the knowledge and skills to handle intricate bending tasks effectively. Seeking professional help ensures that your sheet metal bending requirements are met with precision and efficiency. Don’t hesitate to reach out to experts when needed to achieve optimal results.