If you want to know How to Improve Vision System Inspection & Reduce Visual Errors then this article is absolutely for you.

In any industry, whether it’s manufacturing, logistics, or warehouse operations, visual inspection is a crucial step in the quality assurance process. There are many factors that contribute to visual errors in a system inspection including environmental factors such as lighting and contrast. The human element also plays a role in reducing visual error rates by increasing awareness for potential errors and providing efficient visual inspections.

These are some of the ways to improve the accuracy of your vision system inspection and reduce visual errors.

Table of Contents

Understanding the causes of errors

in your visual inspection process

The primary cause of errors in a visual inspection is the human factor. In order to increase success rates, there are three key factors that need to be considered:

1) Training – To increase awareness for potential errors, you must provide a complete guideline for what’s expected during the execution of an inspection. Training should be scheduled with employees who will participate in inspections and should consist of all relevant information including how to perform the inspection, what to do if they find something unexpected and how to retrace their steps.

2) Visual feedback – It is important that your workers receive feedback on their performance throughout the process. This will highlight areas where they may be making mistakes and allow them to learn from these mistakes.

3) Communication between workers – Communicating with one another will help reduce confusion and provide additional safety measures both before and during an inspection. They also make it easy for you to identify problems as they arise so that corrective action can be taken immediately.

These three factors will equip your employees with the skills necessary for getting the most out of their visual inspection process by reducing errors caused through human error.

Industrial environments and how they affect visual inspections

In any industry, whether it’s manufacturing, logistics, or warehouse operations, visual inspection is a crucial step in the quality assurance process. There are many factors that contribute to visual errors in a system inspection including environmental factors such as lighting and contrast. The human element also plays a role in reducing visual error rates by increasing awareness for potential errors and providing efficient visual inspections.

These are some of the ways to improve the accuracy of your vision system inspection and reduce visual errors:

- Create a structured visual inspection process with pre-determined checkpoints throughout your system

- Utilize mobile devices to gather data during inspections

- Use tools such as reflective markers or retroreflectors to present an object with known alignment

- Eliminate shadows by using light sources such as LED lights or natural lighting

- Keep your work area clean and clutter-free

The human element in inspection and error reduction

System inspection errors we can divide into two categories: operator-based and product-based. Operator-based errors are caused by a lack of accuracy in the inspector’s actions. Such as when an inspector misses or misreads a visual cue, causing them to miss a defect on their product. The machine itself product-based errors, such as when the machine fails to function or produce the correct product.

Operator error is generally easier to detect and reduce than product error. So we recommend that you focus your inspection efforts on operator-based errors first.

There are many things you can do to make your inspection more efficient. Consider implementing these methods for better performance:

- Training

- Awareness training

- Visual cues

- Standard operating procedures

- Documenting inspections

Increase awareness of potential errors

Although visual inspection is a crucial step in the quality assurance process, it can be difficult to detect errors because people are not always conscious of them.

However, by increasing awareness for potential errors and providing efficient visual inspections, the human element can improve the accuracy of your vision systems and reduce visual error rates.

This includes paying attention to environmental factors such as lighting and contrast. For example, when you’re inspecting something bright and shiny like a belt buckle, look for scratches or dirt that may indicate a potential defect. These types of defects are easier to see when it illuminats and contrasts high.

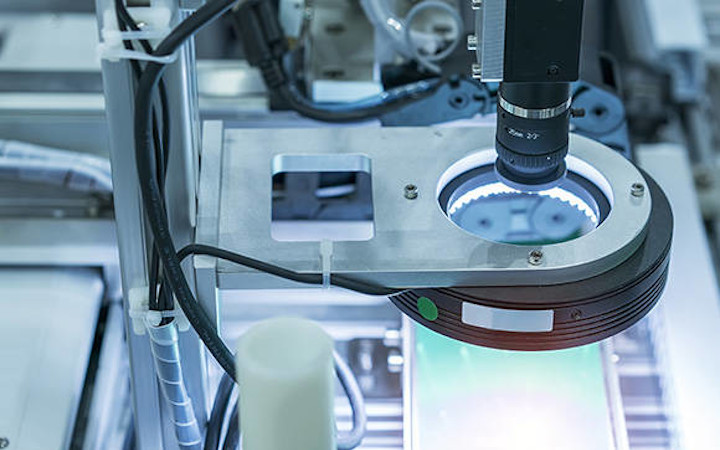

Another way to increase awareness of potential errors is to use cameras during inspections. Cameras provide an eye-level view of the object of inspection which allows an inspector to see any defects more easily.

Additionally, you can add automation into your inspection process by using robotic vision systems such as an industrial robot or an inspection machine with a camera on its head or eyes. This would allow operators to concentrate on other tasks without missing out on any critical information for their operation.

Visual inspection tools.

One way to improve the accuracy of your vision system inspection is by using the right tools and techniques. The use of tools such as a close-up lens or magnifier can significantly increase inspection accuracy. The magnification of image reduces the amount of visual error that occurs due to environmental factors such as lighting and contrast.

Another tool is a high quality video camera. By using a camera, you have an increased awareness for potential errors and provide more efficient visual inspections with less time spent on each area of inpections.

Since these are some of the key things to take into account when inspecting equipment. It’s important that you have enough light in order to clearly see what is happening during your inspection process. You can achieve it through the use of overhead lighting. Or appropriate lighting at the workstation where you are conducting inspections. As part of your inspection plan, it’s also important that you choose an appropriate background color for your workstation. So that both people and equipment are visible during inspections.

To ensure that all aspects of your inspection are conducted efficiently. It’s important that employees receive proper training before starting their journey into visual inspections. With proper training, employees will know how to properly inspect items. And help reduce any bugs or defects before they even occur in the production process.

You can also use the visual inspection process to improve equipment care and maintenance. By inspecting your equipment regularly, you can catch potential problems before they occur and save money in repair costs. For example, if you notice a broken part during your inspection process. It’s important that you report it to a supervisor so that the appropriate steps they can take. This will help ensure that they can correct before any issues arise with the equipment or production schedule.

By taking some of these key aspects into account when conducting visual inspections. You are ensuring that all aspects of your workplace are safe. And efficient for employees as well as customers who may be purchasing products from your organization in the future.