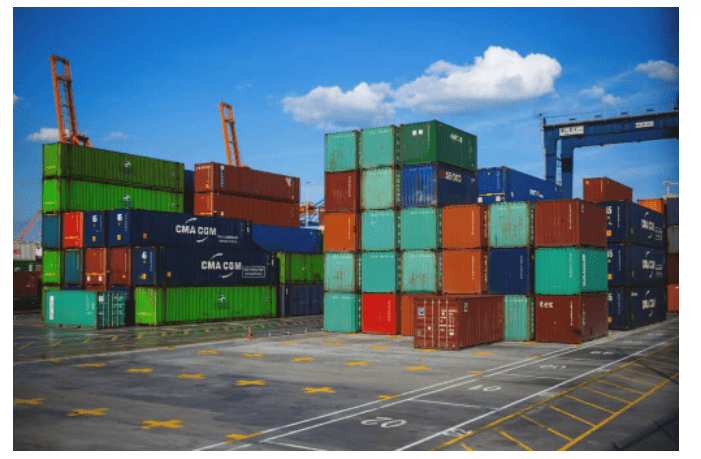

Australia has 2,772 shipping companies, with Sydney being the largest province with a market share of 27%. Loading cargo into shipping containers is a long and careful task that shipping companies must conduct with due diligence. They must consider numerous factors of the national and international laws on goods transport, safety and integrity. The primary objective of the shipping container transport industry is the safe loading and shipment of cargo. Today, the economic growth and technological development, various tools, software, equipment and process standardisation have significantly reduced shipping costs and time and made the process safe.

Table of Contents

What Are the Consequences of Loading Containers Improperly?

The shipping industry faces numerous shipping container accidents due to improper loading despite safety protocols. According to an AMSA report, there were 3,371 marine accidents in Australia. The containers that are not loaded appropriately face the risk of loss or damage to the cargo, endangering the people, marine life and the vehicle. It can also result in massive economic losses for customers and carriers. If the accidents are attributed to poor cargo packing, handling or securing into the shipping transport containers, the shippers are held liable. They must be familiar with the international CTU code and other local body regulations for the safe loading of containers.

Key Steps to Ensure Secure Loading of Shipping Containers

Check the Condition of the Cargo and the Container

When the shipping company readies a container for packing, they need to ensure that it is clean and dry. They need to ensure that it is functional and there are no holes. The floor must not be damaged and must be clear from protruding screws or nails that might cause damage to the cargo. They also must ensure that the container can cater for the necessary payload. The goods must be appropriately packed, marked, and labelled to ensure accuracy in shipment. It is essential to ensure that none of the cargo gets damaged before loading. They can take pictures as records if the goods get damaged due to issues from the third party or consignee.

Choose the Appropriate Shipping Container for Transport

Considering all the factors, the shipper must select the container. Additionally, the container must have adequate ventilation, storage, temperature conditions, weatherproofing, and working doors. Inspectors must check the container for signs of distortion, leaks, odour, chemicals or welding requirements that might damage the goods.

Plan the Loading

The loading process must be well-planned before commencement, considering the load distribution. It must be such that half the container bears less than 60% of the payload. Generally, heavier cargo sits on the bottom, evenly distributed on the floor. It ensures that the container is not heavy on one side, decreasing the risk of toppling. Similarly, wet cargo goes on the bottom, while dry ones go on top. While planning the loading, the supervisors must consider the size, weight, density and the state of the product and ensure no cross-contamination occurs via odour or dust. Shippers must handle hazardous cargo according to the regulations set by the government and the companies. The goods must also not collide and be easily accessible for pickup after the delivery.

Securing the Cargo in the Container

Securing cargo involves ensuring the container stays in the intended position and does not damage itself or other items. The best way to secure cargo in containers is to place them tightly against each other and the walls. In cases when it isn’t possible, shippers must use techniques like bracing, blocking, lashing, fastening, dunnage, strapping or tie downs to protect the cargo from the compressive forces.